On the road again…

Shearwater was loaded on a truck today (US Boat Haulers), bound for San Francisco Bay. With luck she will be in Richmond by Friday and get her first taste of the Pacific Ocean.

Preparing for the transport went amazingly well. On Thursday we started prepping the rig for removal. Boom off and halyards pulled back through the rope clutches to the mast. Then I motored nervously into the very shallow Clear Lake, while Chris drove the car around to South Texas Yacht Services. Pulling the rig turned out to be one of the bigger challenges. The Spar-Tite mast boot wouldn’t release and we started lifting the boat out of the water by the mast. Not the correct way to lift a boat. A few back and forths finally caused it to release with a bang and a shudder. Then Shearwater was hauled and it was clear I wasn’t joking about the shallow water. The bottom foot of the keel was covered in mud. It seems the mud is really, really soft, so we just motor around plowing through the muck half the time without even realizing it. The rest of the bottom of the boat was a definite positive surprise. After 2 years our CopperCoat bottom came out with just a tiny bit of slime on it. Considering the bottom has only been cleaned by a diver 4 times in the past 2 years, I’m really pleased. We touched up a few areas, like the bottom of keel, that had worn off sitting on the sand bar last summer in the Florida Keys and she looks good to go for another few years. In fact, the boatyard guys were so impressed they asked what kind of bottom paint we used. Their comments were “If all boat bottoms looked like this we’d be out of business” and “It looks like this could last another 5 years”.

Once Shearwater was on the stands, we attacked the project list with abandon. The biggie was replacing the front engine mounts with a softer set in hopes of reducing some of the vibration that was happening even in neutral. Then I tackled aligning the prop shaft for the first time and that seemed to have gone well too. The other biggie was some rewiring on the mast, which created a bit of a conundrum. It is obviously much easier to work on a mast lying chest high on sawhorses, but how do you test the wiring to make sure the lights are working without it connected to the boat battery? Two 6 volt flashlight batteries connected in series and a set of alligator clips to the rescue, of course. Worked a treat!

Another cool “project” was picking up our huge K2/A2 spinnaker that we had trimmed down to be the same size as our new A2. It turns out the luff, leech, and foot were nearly the same length, but the girth on the K2 spinnaker was 6 feet wider. Now smaller it should fly the same, be easier to handle, and we probably won’t notice a difference in speed. The ToDo list is really getting down to the last few items now. What a relief! Hopefully, we get to do some nice sailing in SF Bay over the next two months instead of just projects.

If the transport stays on schedule Chris & I will fly to SF on Friday and spend the weekend putting Shearwater back together again.

2 comments

Leave a ReplyCancel reply

Sign up to receive blog updates

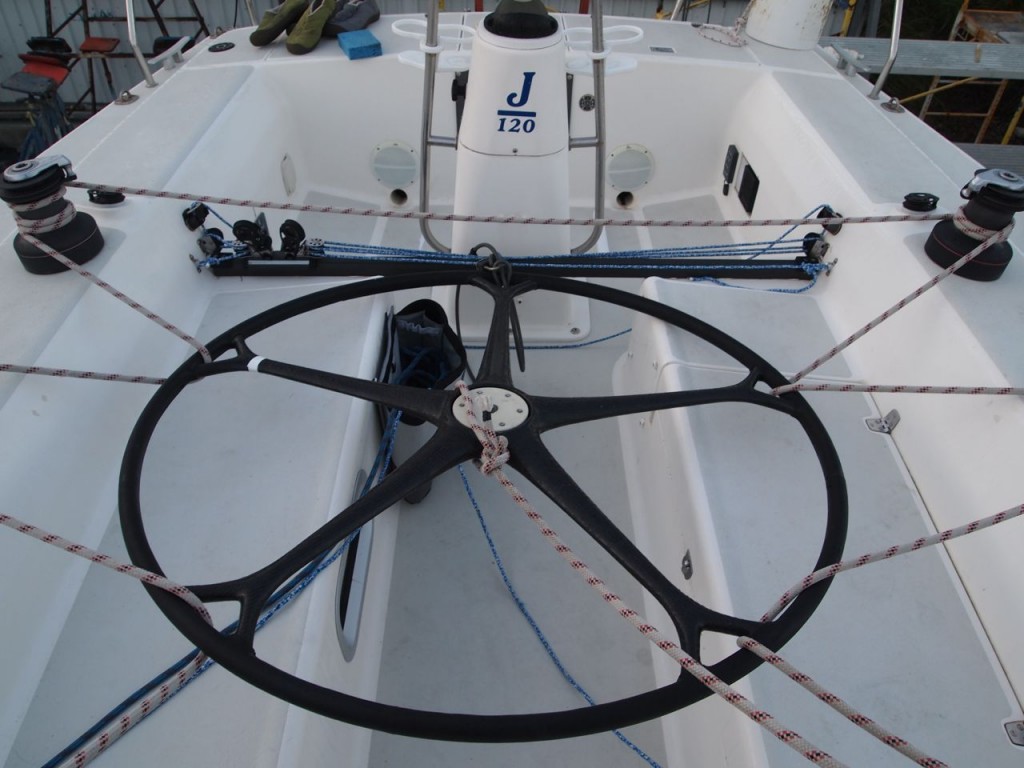

Hi, I just purchased a J120 and are having it shipped. It appears that you removed the bow pulpit to ship over the road, but not the stanchions, was the removal of the bow pulpit completely necessary?

Hi Robert,

Yes, removing the bow pulpit was necessary to keep the overall height below some necessary number. Also, the wheel. It would depend on the trailer, but it seemed like our trailer had the keel about as low as you could. I know some J/120’s had to remove the forward stanchions and cabin top winches. Just depends on the trailer and the route, which have different restrictions.

Stay well.